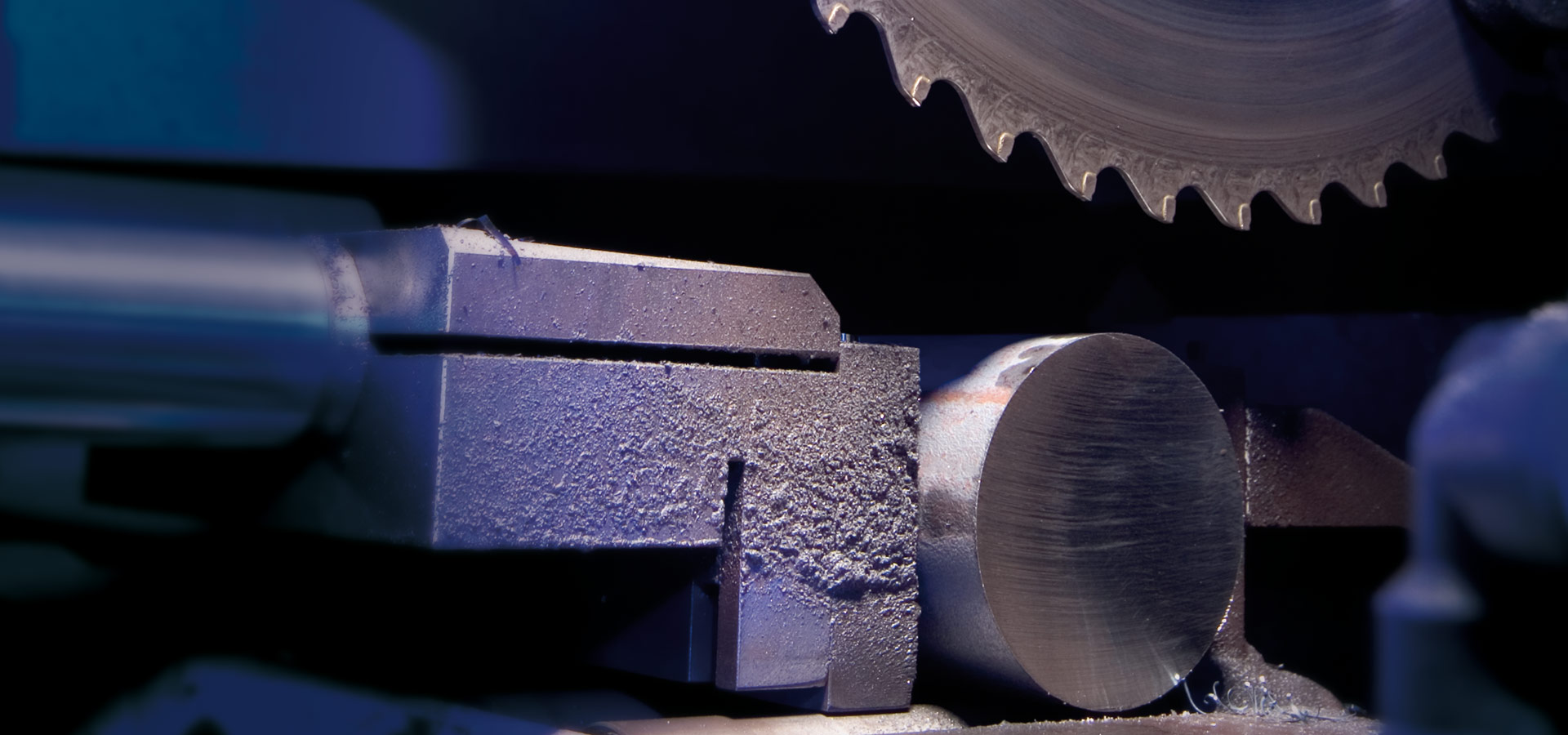

PRE-PROCESSING

Our pre-processing possibilities offer many advantages.

They reduce our customers‘ costs, for example.

A growing degree of cost reduction potential for the manufacturing industry lies in the field of pre-processing. At the same time, the demands on individually tailored steel solutions and the precise processing of steel products for the respective application are constantly increasing. Accordingly, the reduction of vertical integration and the associated integration of competent partners into the value chain go hand in hand with high expectations of cost and benefit effects.

Pre-processing options

Pre-processing options

– Fully automatic band saws

– Fully automatic band saw centers with automated material feed/removal

– Fully automatic circular sawing machines with automated material feed/removal as well as sampling by robots

Wide range of pre-processing options

– Sawing of fixed and exact lengths (internal)

– Cutting to length and bundle cutting (internal)

– Shearing (internal)

– Deburring, (face) chamfering and centering of fixed and manufacturing lengths (internal)

– Marking and labelling (internal)

– Mechanical descaling and blasting (internal/external)

– Heat treatment (internal/external)

– Drilling and deep hole drilling (external)

– Milling (external)

– Zinc coating and priming (external)

Wide range of applications

Pre-processing of

– Bright steel

– Rolled and forged bar steel

– Steel tubes

– Round, hexagonal, square and flat material

Wide range of dimensions with narrow tolerances

Dimensions

10 – 730 mm (band saws)

10 – 150 mm (automatic circular saws)

10 – 50 mm (shear)

Tolerances

max. +/- 0,50 mm (band saws)

max. +/- 0,25 mm (automatic circular saws)

max. +/- 0,30 mm (shear)

Flexible, demand-oriented production

– Individual production

– Small and large series

– Bulk material production (sawing/shearing)

– Production with robot-controlled container or pallet loading according to customer-specific packing instructions (sawing)

Authorized material identification

– Marking and labelling by means of hard stamping (stamp or dot matrix printer) or electrolytic inscription

– Stamping of processed material in agreement with TÜV Nord

– Re-stamping approval of the DNV GL classification society